About Asphalt

Founded 1992 | Highly Rated | Woman-Owned and Family-Operated

Since 1992Highly RatedWoman Owned and Family Operated

Contact Us Now

ABOUT ASPHALT PAVEMENT:

Asphalt pavement is a mixture of bitumen (a liquid asphalt bonding agent) and aggregate (bulk materials such as sand, stone, gravel, pebbles, etc.). The larger the aggregate, the stronger and more durable the pavement. Asphalt can be installed by machine or by hand. Machine installation provides a smoother, more uniform, finish. Some hand installation is almost always required in areas that cannot accommodate the paver. The finish in these areas will be slightly different than that of machine installed areas, but a skilled raker can achieve excellent results.

Once installed the liquid asphalt in your pavement will begin to cure. Newly installed asphalt has a deep black color but as it cures the color will lighten and the asphalt will begin to harden. It is important to keep in mind that the first six to twelve months after installation pavement will remain somewhat soft and pliable. For this reason, extra care should be taken to allow the pavement to cure. Excessive heat will cause asphalt to become softer and more flexible. Cold temperature will cause it to become harder. Since Asphalt pavements are flexible they will conform to the surface beneath them and to the shape of things placed on them. During the winter it is common for the frost in the ground to cause pavement to heave as the ground heaves. Once temperatures warm and the frost leaves the ground the pavement will most likely settle back to its original position. Asphalt’s flexible nature is the reason it is so commonly used in the Northeast, where we experience drastic temperature changes.

INSTALLATION - SELECTING THE OPTION THAT IS RIGHT FOR YOU:

SUB-BASE:

The first and most important factor to be considered prior to the installation of asphalt is the foundation upon which it will be built. New asphalt should be installed on a foundation of properly compacted crushed stone. We use State Approved Item #4 crushed stone with dust, which we wet as we compact to provide a strong solid foundation.

Clay ground conditions may require the installation of a Geotextile Fabric. This Fabric is placed prior to the subbase installation and provides a barrier to prevent the clay from intermingling with the stone which will destabilization the subbase.

ONE COURSE PAVING:

Best suited for residential paving where heavy vehicles will not be placed on the pavement. Installation consists of a single layer of asphalt approx. 3” thick before compaction. Type 7 asphalt contains fine stone and dust which has a very smooth finish. Type 6 asphalt contains slightly larger stone, so it provides more strength but is not quite as smooth as Type 7. Once Sealcoated it is difficult to distinguish the difference in the textures.

TWO COURSE PAVING:

Best suited for commercial and/or residential paving where there is the expectation of heavy traffic or heavy vehicles. This consists of two layers of pavement (a Binder course and a Top course) with compaction being performed after the installation of each course. First, the Binder Course containing large stones is installed, this provides strength. Second, a Top Course containing smaller stone is installed for a smooth finish.

PAVEMENT RESURFACING or OVERLAY:

Paving over already existing pavement often requires saw-cutting and removing existing pavement at garages, sidewalks, the street, etc. to provide abutment of the new pavement. The existing pavement is then true & leveled to remove any low areas. Once prepped a layer of pavement approx. 1½” -2” if installed and compacted.

It is important to note that new pavement will conform to the surface upon which it is installed. For example, if the old driveway has cracks, eventually they will make their way up to the surface. This is referred to as reflective cracking.

About Saw-cuts and Milling:

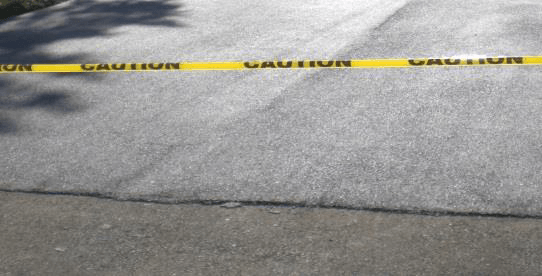

These procedures ensure that your pavement will meet flush with the road, sidewalks, and other structures. When pavement isn’t flush it can cause a trip hazard. At the road, if the pavement isn’t flush, it can be damaged from plows catching the lip.

Driveway Not Saw-cut to Meet Flush at Road- This Can Result in Plow Damage